This workshop is an introduction to the application of parametric design tools and digital fabrication techniques in relation to materiality. It consists of a software workshop, project tutorials, an introductory lecture, and a final presentation session.

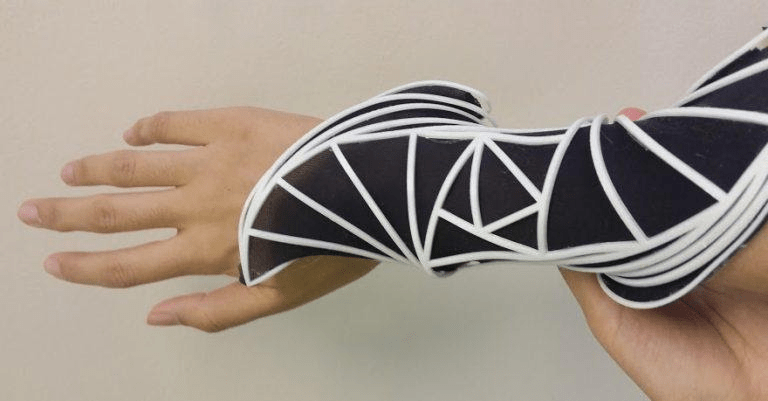

Our design brief’s aim is to develop an innovative, research-driven design wearable prototype (hat, mask, piece of jewelry, etc) using parametric tools in coherence with 3D printing and one primary related material (e.g. TPU95, PLA,) applied on a pre-stressed membrane. To achieve this, we will explore the use of the simulation plug-in Karamba, thus we can utilize the stress lines of a preferred shape as a form-finding mechanism for our composite panels. In particular, we will start with digital 3D patterns linked to the panel’s simulated stress-lines, rationalize them and then emboss them, before laminating them onto a pre-stretched membrane in order to transform it into a three-dimensional shell.

For our physical models, we will use elastic viscose, latex or lycra sheets, as well as semi-elastic flexible PLA/TPU filaments and super glue. The required parametric tools include Rhino6, Grasshopper, and the grasshopper plugins Karamba and paneling tools.

Participants: approx. 24 students for Karamba 3D, 48 students for dmakerlab

Submissions: To be announced later